|

Industrial Filters

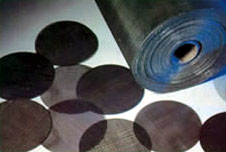

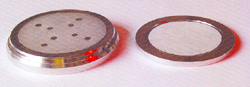

Disc Screen

Wire mesh disc filters:

single layer

disc filters ;

multi-layered

disc filters.

Disc Filters Shapes: round, square, oval or to

be made according to customer's requirements.

Disc Filters Material: Black iron, stainless steel, brass, etc.

Fineness of disc filters: from 2mesh to 400mesh

Diameter of the wire mesh disc screen: from 10mm to 580mm (1/8" to 22")

Double layered disc

Plain steel disc

Stainless steel disc

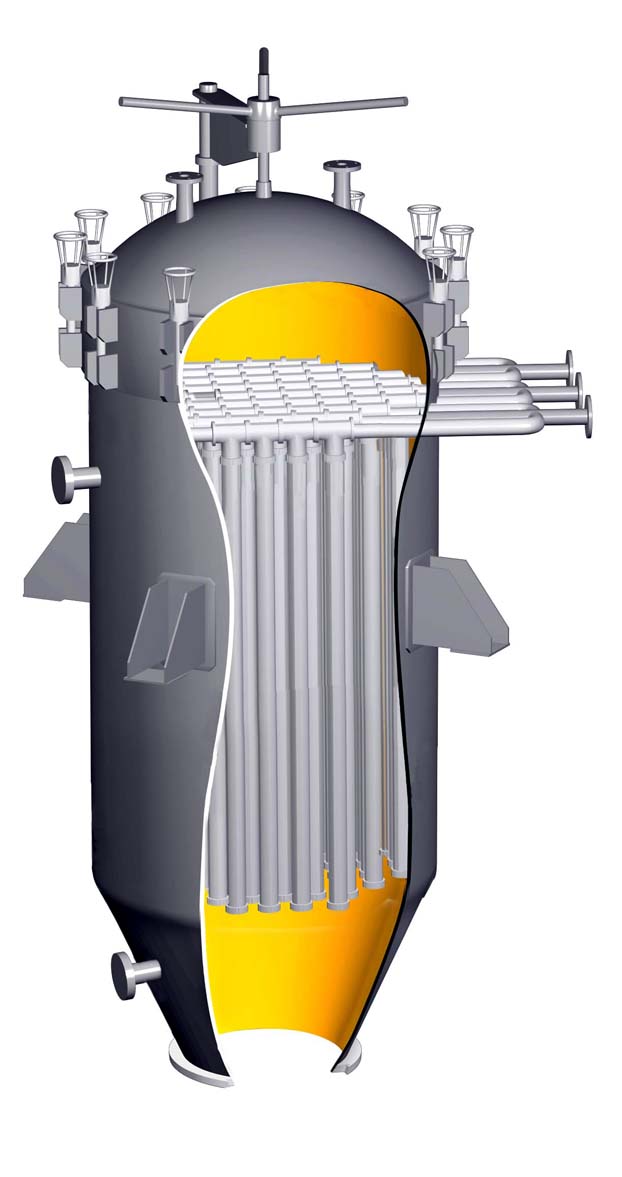

Filter leaf

Filter leafs are designed for batch operation in high

flow rates and low solids removal

with applications up to 6 wt% solids loadings,

depending upon application.

All units provide maximum filtrate clarity.

Two kinds of filter leaf are available to suit your process

requirements:

· Metal Screened

Filter Leaves

· Polypropylene

Filter Leaves for low temperature or corrosive applications

Sky Mesh Group also provides full filter system including

vessels, agitating tanks and accessories.

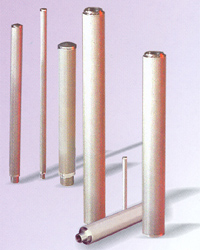

Self-cleaning candle

filter elements

|

Area series

(M2)

|

Tube body

diameter

(mm)

|

Working

pressure

(MPa)

|

Operating

temperature (oC)

|

Nominal

filter precision (µm)

|

|

0.25 - 100

|

300, 400,

500, 600, 800, 1000, 1200, 1400, 1600, 1800

|

0.4

|

120

|

1, 5, 10,

15, 25, 40, 50, 65, 75, 80, 100, 120, …

|

Sky Mesh Group also provides various

filters including:

* Automatic plate type hermetic filter

* Vertical leaf filter

* Horizontal leaf filter

* Multifunctional filter

* Bag filter

* Horizontal paper plate filter

* Candle filters

Pleated Filter Elements

Filter media for Pleated

Filter Elements are stainless steel sintered fiber web and stainless steel

weaving wire cloth.

Stainless Steel Sintered Fiber Web is a kind of durable and pleatable 316L

stainless steel medium, sintered into a graded pore structure, enjoys the

advantages of high porosity rate, more filtration area, high dirt holding

capacity and can be repeatedly used.

Stainless Steel Woven Wire Cloth is made by weaving of stainless steel wire

in a variety of diameters. Filter elements with stainless steel woven wire

cloth as filter medium, enjoy such advantages of good strength, fastness,

easily cleanable, heat-resistance and economic cost.

Pleated Filter Elements mainly serve in filtration of high molecular

polymer, long fiber, short fiber, meltdown in thin film production, also

drugs, hydraulic oil, disposal of water, hot gas, etc.

Cylindrical Filter Elements

Cylindrical Filter Elements are made with Five-Layer Sintered Wire Cloth,

with filter rating ranging from 0.5micron to 200micron. Cylindrical filter

elements mainly serve in filtration of polyester, oil products, chemicals

and pharmaceutics, also used in filtration of pure water and gas.

Five-Layer Sintered Wire Cloth

consists of five layers of stainless steel wire mesh, which are sintered

together in vacuum. Cylindrical Filter Elements made of Five-Layer Sintered

Wire Cloth as filter medium, boast of fine micron filtering, good

permeability, high strength, easy to clean, good corrosion resistance,

durable at work and no immigration of materials.

Disc filters

Filter Media:

Filter medium for Disc Filters is multi-layer sintered wire cloth, with a

rating range from 0.5 to 200micron, in a diameter from 200mm to 3000mm. Disc

filters with multi-layer sintered wire cloth as filter medium, enjoy good

strength, accurate filter rating, long life-span and repeatedly cleaning.

Materials: Standard material of disc filters is SUS316L. Other metals

like Nickel alloy or Titanium alloy are also available at customers request.

Application: Disc filters are ideal filter fittings for three-in-one

filtration ( filtering, washing and drying ) in pharmaceutics, food,

chemical industries and polymers. Disc filters work as a complete unit or in

parts.

|

|

| |

|

| |

|

| |

|

| |

Wire Materials: Stainless steel wire, copper

wire, galvanized iron wire, polyamide fiber or

F46 wire. |

| |

Process: Crochet weaving. |

| |

General Use: Filter mesh for gas and liquid

serves well in filtering and deleting the

particle mixture in foam, liquid and air, by way

of distillating, absorbing, evaporating and

filtering process, in petroleum, chemicals,

metallurgy, machine, pharmaceuticals, automobile

and environmental protection. |

| |

|

| |

|

Specification List of

Filter Mesh |

| Model |

Specification |

Wire Diameter

mm |

Materials |

Area/Weight

m2/kg |

Technical Notes |

| Standard |

40-100 Model 60-150 Model

140-40 Model

40-100 Model

40-100 Model

40-100 Model

40-100 Model |

0.1x0.4 0.1x0.4

0.1x0.4

0.27

0.1x0.4

0.25

0.2 |

stainless steel wire stainless steel

wire

stainless steel wire

gal. iron wire

copper wire

polyamide fiber

PVC fiber |

1/0.5 "

"

1/0.7

|

1, For 40-100 model: 40 holes in 100%

width 2, Metal filter mesh can be

processed into weaves type |

| High Efficience Model |

60-100 Model 80-100 Model

90-150 Model

200-400 Model

60-100 Model

80-100 Model |

?é.012 0.1x0.3

0.1x0.3

0.1x0.3

0.1x0.3

?é0.1-0.15

0.1-0.15 |

stainless steel wire stainless steel

wire

stainless steel wire

stainless steel wire

polyamide fiber

polyamide fiber |

1/0.6 1/0.6

1/0.6

1/0.6

|

|

| High Permeability Model |

30-100 Model 30-150 Model

70-400 Model |

0.1x0.4 0.1x0.4

0.1x0.4 |

stainless steel wire stainless steel

wire

stainless steel wire

stainless steel wire |

1/0.4 1/0.4

1/0.4 |

|

|

|

|

| |

|